The Benefits of Custom Sheet Metal Fabrication for HVAC Installations

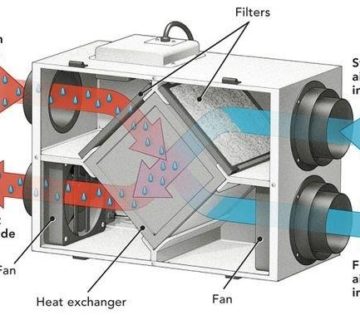

In the HVAC industry, efficiency and performance are critical to ensuring client satisfaction and system longevity. One way to achieve these goals is through custom sheet metal fabrication. Custom fabrication allows for the precise creation of ductwork and other components tailored to the specific needs of each project. This blog post explores the benefits of custom sheet metal fabrication for HVAC installations and highlights examples of successful projects.

Enhanced Efficiency and Performance

1. Perfect Fit and Function:

Custom sheet metal fabrication ensures that each component is precisely crafted to fit the unique specifications of the building and HVAC system. This perfect fit minimizes air leaks and maximizes airflow, leading to more efficient heating and cooling. With custom ductwork, you can avoid common issues like uneven air distribution and temperature variations.

2. Improved Airflow:

Properly designed and fabricated sheet metal components can significantly enhance airflow within the HVAC system. Custom ducts, transitions, and fittings reduce resistance and turbulence, allowing air to flow more smoothly and efficiently. This improvement in airflow translates to better system performance and lower energy consumption.

3. Durability and Longevity:

Custom sheet metal components are built to last. High-quality materials and precise fabrication techniques result in durable parts that can withstand the demands of HVAC systems. By investing in custom fabrication, you can reduce the need for frequent repairs and replacements, ultimately saving time and money

4. Improved Airflow:

Custom sheet metal fabrication also offers the advantage of aesthetic integration. Components can be designed to blend seamlessly with the building’s architecture, ensuring that the HVAC system is not only functional but also visually pleasing. This is particularly important in commercial spaces where the appearance of exposed ductwork can impact the overall design.

Examples of Successful Projects

1. Custom Ductwork for a Historic Building:

In a recent project, EDI HVAC&R provided custom sheet metal fabrication for a historic building undergoing renovation. The building’s unique architecture required specially designed ducts and fittings to preserve its aesthetic appeal while ensuring optimal airflow. The custom components seamlessly integrated with the structure, maintaining the building’s historic charm while enhancing its HVAC system’s efficiency.

2. Optimized Airflow in a Commercial Office:

A commercial office space faced challenges with uneven temperature distribution and high energy costs. EDI HVAC&R designed and fabricated custom ductwork that addressed these issues by optimizing airflow and reducing air leakage. The result was a more comfortable indoor environment and a significant reduction in energy consumption, leading to lower operating costs for the client.

3. Residential Customization for Comfort:

In a residential project, a homeowner required a unique HVAC solution for a multi-level home with varying heating and cooling needs. EDI HVAC&R fabricated custom ducts and registers tailored to each room’s specific requirements. The customized system provided consistent temperature control throughout the home, enhancing comfort and energy efficiency.

Conclusion

Custom sheet metal fabrication offers numerous benefits for HVAC installations, including improved efficiency, performance, durability, and aesthetic integration. By choosing custom components, you can ensure a perfect fit and function, resulting in optimal system operation and client satisfaction. At EDI HVAC&R, we specialize in providing high-quality custom sheet metal fabrication for all your HVAC needs. Contact us today to learn more about how we can support your next project.